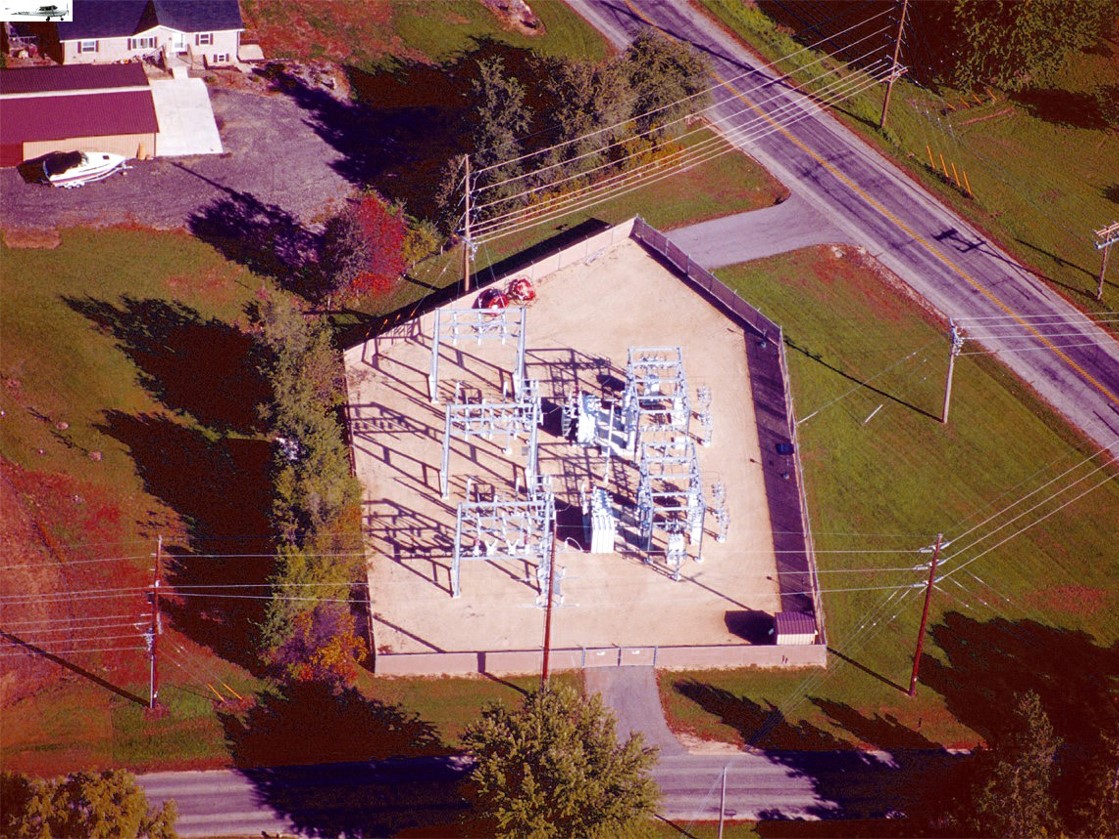

Testing and documentation is an important part of the work we do at Forster. Accurate measurements reduce environmental and voltage issues that could cause problems in the future. We are also home to one of the few places to perform cable testing in the United States. Everything we do is to help make your job easier and keep your customers happy.

Soil Resistivity Measurements

Forster Electrical Engineering will provide measurements required for designing a grounding grid system for substations and other electrical systems.

Ground Grid to Earth Resistance Measurements

We will provide the measurements necessary to verify the ground grid earth resistance meets or exceeds specific design criteria.

Stray Voltage Measurements in Cow Contact Areas

Stray voltage electrical investigations identify stray voltages of concern relative to dairy operations. Stray voltage testing results are provided in a report.

Power Quality Measurements

You may have power quality concerns regarding sensitive electrical equipment installed on a distribution system. We can identify areas of concern, locate the cause, and recommend solutions to mitigate power quality concerns.

Line Inventories/Record and Data Collection

Forster Electrical Engineering will obtain and document overhead and underground distribution line inventories on your electrical system.

GPS Location of Equipment, Poles, and Distribution Lines

Our staff can create GPS locations of electrical equipment and integrate this information with a GIS map to be used for design purposes.

RUS/CFC Inspection of Distribution Lines

Our experienced personnel will perform annual inspections of underground and overhead lines to verify they conform with applicable RUS and CFC codes and standards. Upon completion of construction work orders, line inspections are completed as required for RUS compliance.

Pad-Mounted Equipment and Pole Inspections

Pad-mounted electrical equipment inspections verify equipment is in proper working order and installations meet codes and design standards.

Utilizing the hammer/sound/visual test, we inspect poles two feet below grade for rot. We visually inspect poles above grade for deterioration from birds, insects, lightning, weather, etc. and issue a report for each pole inspected.

On-Site Construction Supervision

On an as-needed basis, our staff will provide on-site construction supervision to address construction issues and to verify installations are completed in accordance with the plans and specifications.

Random Sample Examination of New Cable

We will provide incoming cable quality control inspection at a reasonable cost. When you instruct your cable manufacturer to send us a sample as each reel is shipped from the factory, we will provide you with a testing report prior to cable installation. If a cable does not meet industry standards or your specifications, we will notify you immediately, give you our opinion on the cable, and contact the manufacturer for its comments. In almost every case, the manufacturer is eager to correct problems and maintain a high level of cable quality.

Our testing is designed to provide the highest cost/benefit ratio. Although factory testing exceeds incoming quality control testing, and the quality of cable produced in North America is excellent, we detect “bad days at the factory”. If testing indicates the quality of your cable is high, you will have a firm basis on which to develop confidence in your cable manufacturer.

Forster Electrical Engineering is recognized by the National Electric Cooperative Association as an approved insulated power cable testing laboratory.

Microscopic Cable Analysis

We will provide testing on failed cables or check existing cables using two-foot samples that can be conveniently removed from service and sent to our laboratory. Each sample will be tested for contaminants, water ingress, and treeing to determine the extent of cable degradation that may have occurred. Testing results can be used to prioritize replacements, allocate maintenance dollars to locations needing the most attention, and establish budgets for future work.

Power cables are usually not replaced after the first failure. Assuming a failure appears to be internal to the cable itself, our examination will provide the data necessary to make an informed decision regarding cable replacement. No test or testing laboratory can accurately predict the next failure, but we can provide valuable insight into the condition of a cable.

Failure Analysis of Cable Splices and Terminations

We will provide testing on failed splices, terminations, and elbows using two-foot samples of cable beyond the failure point. We will check for product deficiencies and installation errors. If we identify a product deficiency, the manufacturer can be contacted for an appropriate resolution. If we identify an installation error, future failure can be prevented through training and supervision.

Electrical System Overview Maps

It is essential to have an up-to-date map of a distribution system for contingency switching or planned maintenance. We document existing three-phase distribution systems and prepare overview maps to be used for switching purposes and system planning.

Facilities Mapping with Links to Database Records

Computers (and drafting programs that are run on them) have changed considerably since electrical systems were first drawn on a computer. These systems may now be moving toward database mapping. We can assist with combining detail maps into one drawing and setting up viewports for various detail maps. This will allow for a more seamless set of detail maps. Changes made on a master file would automatically update the detail maps.

GIS Mapping

GIS mapping can be a useful tool for designing electric lines and managing assets of an electrical system. Our involvement includes listening to needs and long term goals prior to implementing a full GIS mapping system. GIS technology in managing an electrical distribution system facilitates easier planning, faster and more accurate electrical design, and up-to-date record data